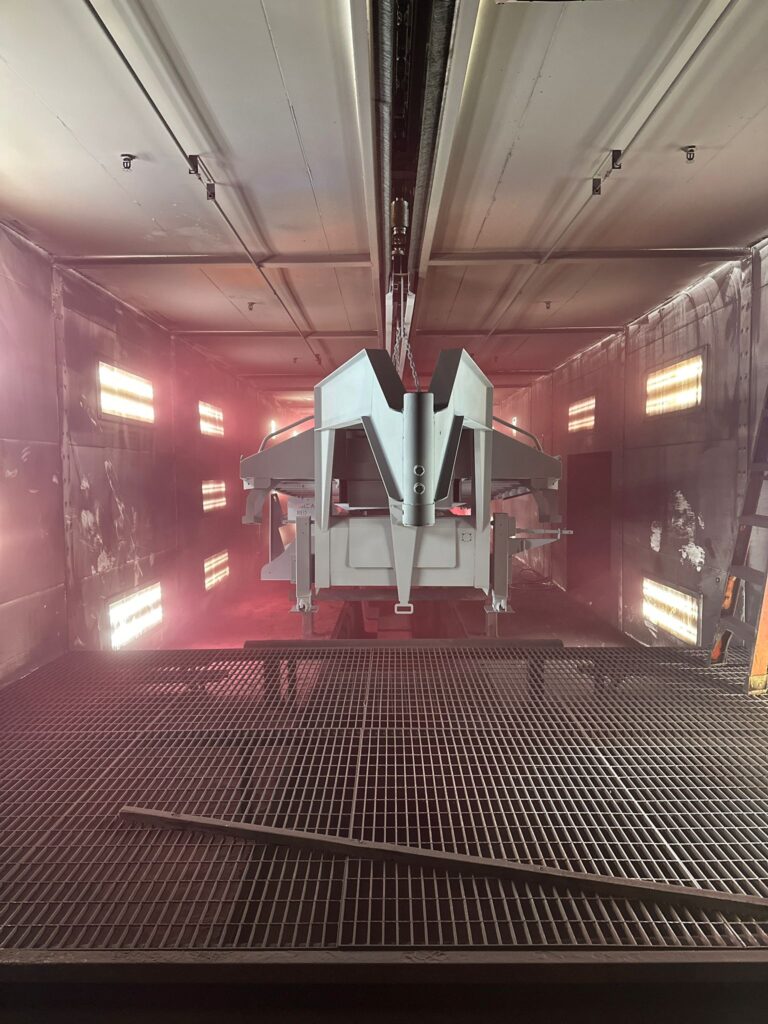

A quality powder coat finish makes all the difference. Our 6 Step Powder Coating Process uses the Sherwin Williams Powdura OneCure product to deliver a durable, high-quality finish. A beautiful high gloss finish is important, but the backbone of any coating system is in the prep. This is how our industry-leading process protects your trailer.